Collect both imagery and thickness measurements in one single inspection

Our underwater drones are exceptional tools for underwater visual inspections. By integrating the Cygnus Ultrasonic Thickness Gauge with our Blueye X3, it is possible to collect both imagery and thickness measurements in one single inspection. Hence, reducing unnecessary risk, time spent, and expenses. The integration displays live imagery and thickness measurements on the same screen, which is perfect for remote inspections.

Thickness measurements in NDT and UWILDs

Ship inspections have come a long way in implementing Non-destructive testing (NDT) and Underwater Inspection in Lieu of Dry-Docking (UWILD). These methods reduce the costs and time of inspections considerably by avoiding dry-docking and damage to the inspection part. Divers have commonly been used, which is a considerable risk to human life.

The newest technology in ultrasonic thickness measurements (UTM) allows the Cygnus probe to measure through coatings and soft marine growth, omitting the need for divers to conduct thickness measurements. By using the X3 with the ultrasonic thickness gauge in inspections you are eliminating the risks associated with the use of divers, and at the same time minimizing time spent and use of resources.

Underwater thickness measurements are not only relevant to ship hulls; pipes, tanks, rigs, ports, and other constructions must be regularly inspected, and the reduction of time, costs and risk applies to these industries as well. This integration will not only reduce the complexity of an inspection but also allow you to reach inspection areas where using heavy ROVs and divers is not possible.

Our Blueye X3 with the Cygnus Ultrasonic Thickness Gauge is able to measure through coatings and soft marine growth, enabling you to conduct thickness measurements without using divers.

The user-friendly X3 with the thickness gauge is suitable for both ad-hoc inspections and periodic inspections. This applies to inspections within several industries such as shipping, offshore, aquaculture, and general underwater constructions.

Software

Our integration of the Cygnus Thickness Gauge is unique for many reasons. We have integrated the ultrasonic thickness gauge to our own Blunux operative system and Blueye App. This is how the thickness measurements are displayed in the Blueye App within seconds without the need for additional software or hardware. The integration also allows you to share your live thickness measurements remotely, and include the readings in the automatically generated inspection report.

Material selection

The shape of the X3 and the probe enables you to take measurements on small, narrow surfaces as well as large constructions. Because there are numerous possible surfaces to measure, we have made it easy for the operator to choose the correct material by implementing a material selection in the Blueye App.

The operator simply selects the material in a drop-down menu, and the material type can be changed at any time. This way, you can measure the thickness of different materials in one single dive.

Remote inspections

The possibility to operate the X3 without additional personnel, combined with live readings in the app, makes this integration optimal for remote inspections. You can easily share your inspection with live measurements and imagery through Microsoft Teams. Internal and external stakeholders can follow the inspection live and give feedback while diving. This ensures that the inspection is meeting all the stakeholder's requirements, and can prevent the need for additional inspections. Learn more in our Help Center article on how to stream your inspections in Microsoft Teams.

Reporting and video overlay

The documentation of an inspection is just as important as the inspection itself. The thickness values are included as an overlay on the recordings and still pictures during a dive, and the still pictures you take will appear in an automatically generated report. The report can be shared immediately, and you have the option to edit the report in Microsoft Word to add additional comments.

Different companies and inspections will have different requirements for the report. Writing reports can be time-consuming, and quick solutions will considerably decrease time and expenses. To easily generate reports for your periodic inspections with your Blueye drone, you can create a custom report template to fit the requirements of your report.

Hardware integration

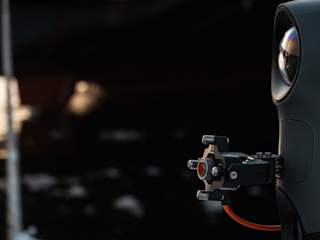

We have mechanicaly integrated the Cygnus in a way that maintains the hydrodynamic shape of the X3. The gauge body is mounted on top of the battery tube to minimize the drag of the drone. Customized buoyancy material is added to obtain a neutral pitch which minimizes the effect on the maneuverability of the X3.

The probe is integrated at the middle front of the X3 with the Cygnus G1 probe handler. You will be able to observe the probe by tilting down the built-in camera. This way, you can do recordings both with and without the probe in the screen in the same dive.

Summary

The integration of Cygnus Thickness Gauge to our Blueye X3 allows you to measure thickness underwater in a safe, efficient and easy way. The gauge is not only attached to the X3, but integrated in a way that gives an excellent user experience. If you have questions about this integration or any other of our products, please contact us.